-

-

Pools

Recommended productsBasen drewniany 434 cm x 401 cm x 118 cm ONYX ABATEC11,999.00 złCanadian steel pool round Ø240 x 120 cm KEA GRE5,920.00 zł

- Pool chemistry

-

Pool cleaning

Our tipsRecommended productsZODIAC CNX-Li 52 iQ FREEDOM cordless pool cleaner, cleans the bottom, walls and waterline4,299.00 zł 5,699.00 złRechargeable pool vacuum cleaner PK GIANT BWT1,399.00 złAutomatic Robotic Swimming Pool Cleaner ZODIAC CNX 253,219.00 zł 4,439.00 zł

- Pool heating

-

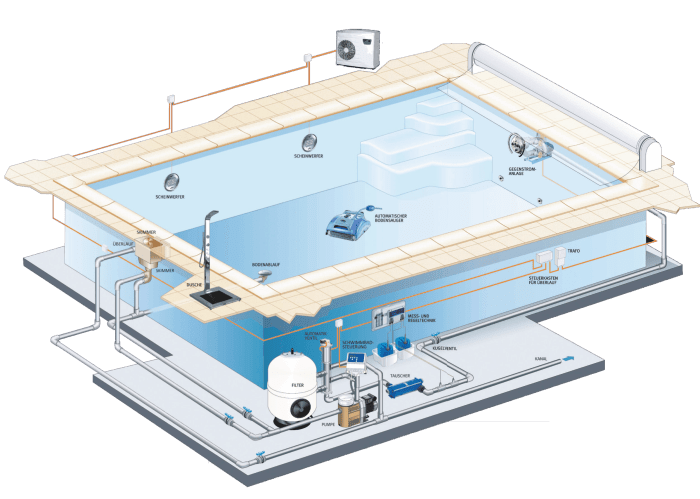

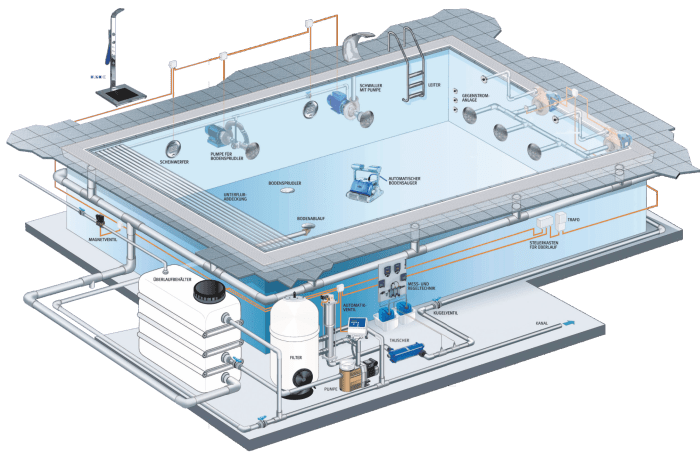

Pool technology

Recommended productsSafety cover for swimming pool 6 x 3m type Basic6,848.10 zł 7,609.00 złUV Lamp for 75W UV-C BUDGET XCLEAR879.00 zł

- PVC-U & PE fittings

-

SPA & Wellness

Recommended productsElectric sauna heater HARVIA VEGA BC60 6,0kW1,499.00 złElectric sauna heater HARVIA CILINDRO PC90 9,0kW2,359.00 złWood sauna ladle 48CM HARVIA95.00 zł

- Pool building